EthosEnergy secures deal to provide block transformer for Enea Połaniec

EthosEnergy secures deal to provide block transformer for Enea Połaniec

|

News

|

10 April 2024

|

|

EthosEnergy selected as approved repair facility by Amarinth in Middle East

EthosEnergy selected as approved repair facility by Amarinth in Middle East

|

News

|

27 March 2024

|

|

EthosEnergy rolls out Performance Center for remote energy operations

EthosEnergy rolls out Performance Center for remote energy operations

|

News

|

14 March 2024

|

|

Catching up with Daniel Tegtmeier, EthosEnergy’s Performance Center Director

Catching up with Daniel Tegtmeier, EthosEnergy’s Performance Center Director

|

Views

|

14 March 2024

|

|

EthosEnergy strengthens partnership with Harbour Energy

EthosEnergy strengthens partnership with Harbour Energy

|

News

|

08 February 2024

|

|

EthosEnergy and Raban Al-Safina Group sign joint venture agreement in Iraq

EthosEnergy and Raban Al-Safina Group sign joint venture agreement in Iraq

|

News

|

06 February 2024

|

|

EthosEnergy celebrates new partnership and Abu Dhabi facility success

EthosEnergy celebrates new partnership and Abu Dhabi facility success

|

Social

|

23 January 2024

|

|

EthosEnergy CEO Ana Amicarella is a 2023 Influential Women in Energy Honoree

EthosEnergy CEO Ana Amicarella is a 2023 Influential Women in Energy Honoree

|

News

|

20 December 2023

|

|

Rotor LTE and EcoView™ for Greener Operations

Rotor LTE and EcoView™ for Greener Operations

|

Impact

|

13 December 2023

|

|

Localisation: a key factor in a sustainable energy market

Localisation: a key factor in a sustainable energy market

|

Views

|

01 December 2023

|

|

Entering the field: A peek behind the scenes from EthosEnergy’s VP of Field Services

Entering the field: A peek behind the scenes from EthosEnergy’s VP of Field Services

|

Views

|

30 November 2023

|

|

The circular economy: a key factor in a sustainable energy market

The circular economy: a key factor in a sustainable energy market

|

Impact

|

28 November 2023

|

|

Data at the heart of ESG reporting: the benefits for industry, customers and investors

Data at the heart of ESG reporting: the benefits for industry, customers and investors

|

Impact

|

14 November 2023

|

|

A Year of Growth and Learning: EVP, Patricia Gonzalez, Shares Key Takeaways and Market Outlook

A Year of Growth and Learning: EVP, Patricia Gonzalez, Shares Key Takeaways and Market Outlook

|

Views

|

08 November 2023

|

|

ECOMAX® a finalist for the Gulf Energy Excellence Awards

ECOMAX® a finalist for the Gulf Energy Excellence Awards

|

Views

|

07 September 2023

|

|

EthosEnergy shortlisted for third consecutive Energy Industries Council award

EthosEnergy shortlisted for third consecutive Energy Industries Council award

|

Impact

|

17 August 2023

|

|

How EcoView™ is leading the way for ESG transparency

How EcoView™ is leading the way for ESG transparency

|

Impact

|

19 July 2023

|

|

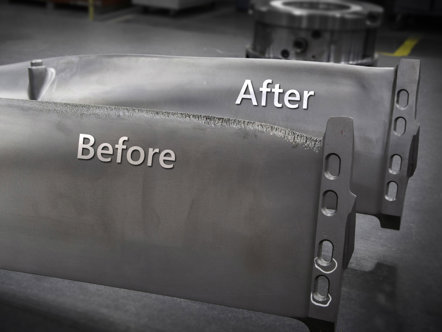

EthosEnergy steam turbine blade services: Repair, don’t replace

EthosEnergy steam turbine blade services: Repair, don’t replace

|

Impact

|

28 June 2023

|

|

EthosEnergy launches EcoView™, industry first CO2 assessment tool for gas turbine rotors

EthosEnergy launches EcoView™, industry first CO2 assessment tool for gas turbine rotors

|

News

|

21 June 2023

|

|

Training for North Sea offshore personnel on SGT-200-1S gas turbines

Training for North Sea offshore personnel on SGT-200-1S gas turbines

|

Impact

|

13 June 2023

|

|

First Solar Compressor Repair in EthosEnergy Middle East Workshop

First Solar Compressor Repair in EthosEnergy Middle East Workshop

|

News

|

23 May 2023

|

|

EthosEnergy Extends Operations and Maintenance Contract of ExxonMobil Cogeneration Facility

EthosEnergy Extends Operations and Maintenance Contract of ExxonMobil Cogeneration Facility

|

News

|

09 May 2023

|

|

Interview with EthosEnergy’s VP of Union Field Services

Interview with EthosEnergy’s VP of Union Field Services

|

Views

|

03 May 2023

|

|

EthosEnergy keeps Telfer site operational during cyclone

EthosEnergy keeps Telfer site operational during cyclone

|

News

|

03 May 2023

|

|

EthosEnergy: A reliable partner in the nuclear power industry

EthosEnergy: A reliable partner in the nuclear power industry

|

Impact

|

28 April 2023

|

|

EthosEnergy awarded Long-Term Service Agreement with GPSC

EthosEnergy awarded Long-Term Service Agreement with GPSC

|

News

|

28 March 2023

|

|

EthosEnergy appoints former ItalPresseGauss CEO, Mario Cincotta as new East Hemisphere Executive Vice President

EthosEnergy appoints former ItalPresseGauss CEO, Mario Cincotta as new East Hemisphere Executive Vice President

|

News

|

14 March 2023

|

|

Knowledge and experience: a key value at EthosEnergy

Knowledge and experience: a key value at EthosEnergy

|

Impact

|

08 February 2023

|

|

A 2022 Review: EU Energy Crisis and the Growth of Hydrogen Technology

A 2022 Review: EU Energy Crisis and the Growth of Hydrogen Technology

|

Views

|

17 January 2023

|

|

Artificial intelligence, gas turbines and poems, oh my!

Artificial intelligence, gas turbines and poems, oh my!

|

Views

|

16 December 2022

|

|

3 proven methods for restoring your last-stage steam turbine blades to as good as new

3 proven methods for restoring your last-stage steam turbine blades to as good as new

|

Views

|

29 November 2022

|

|

Supply chain partner for the future of energy

Supply chain partner for the future of energy

|

Views

|

17 November 2022

|

|

PoliTO and EthosEnergy: Partners on an exciting hydrogen journey

PoliTO and EthosEnergy: Partners on an exciting hydrogen journey

|

News

|

16 November 2022

|

|

Powering the Global Energy Transition with Hydrogen Technology

Powering the Global Energy Transition with Hydrogen Technology

|

News

|

10 November 2022

|

|

New Middle East regional hub positions EthosEnergy for future growth

New Middle East regional hub positions EthosEnergy for future growth

|

News

|

02 November 2022

|

|

Inspiring hydrogen energy stories: Wood’s hydrogen technology

Inspiring hydrogen energy stories: Wood’s hydrogen technology

|

News

|

06 October 2022

|

|

Our Hydrogen Future: Decarbonizing without deindustrializing

Our Hydrogen Future: Decarbonizing without deindustrializing

|

News

|

12 September 2022

|

|

CEO Ana Amicarella named finalist for Power & Energy Female Executive of the Year Award

CEO Ana Amicarella named finalist for Power & Energy Female Executive of the Year Award

|

News

|

08 September 2022

|

|

EthosEnergy's Rayong Facility turn 6S activity into positive environment impact

EthosEnergy's Rayong Facility turn 6S activity into positive environment impact

|

News

|

07 September 2022

|

|

Patricia Gonzalez as EthosEnergy's new Executive Vice President, West Hemisphere

Patricia Gonzalez as EthosEnergy's new Executive Vice President, West Hemisphere

|

News

|

06 September 2022

|

|

EthosEnergy nominated for Optimisation Award at the EIC Awards 2022

EthosEnergy nominated for Optimisation Award at the EIC Awards 2022

|

News

|

23 August 2022

|

|

Why hydrogen energy is the future and how you can be a key part of it

Why hydrogen energy is the future and how you can be a key part of it

|

News

|

04 August 2022

|

|

EthosEnergy Welcomes Piemonte Regional Minister to Italian Facility

EthosEnergy Welcomes Piemonte Regional Minister to Italian Facility

|

News

|

02 August 2022

|

|

EthosEnergy promotes innovative and sustainable solutions for the energy industry in Israel

EthosEnergy promotes innovative and sustainable solutions for the energy industry in Israel

|

News

|

21 July 2022

|

|

EthosEnergy hosts second “Our Hydrogen Future” roundtable event promoting collaboration and partnership in meeting EU emissions targets.

EthosEnergy hosts second “Our Hydrogen Future” roundtable event promoting collaboration and partnership in meeting EU emissions targets.

|

News

|

16 June 2022

|

|

EthosEnergy: On a mission to make energy affordable, available and sustainable

EthosEnergy: On a mission to make energy affordable, available and sustainable

|

News

|

26 May 2022

|

|

EthosEnergy Union Field Services wins silver at Safety Excellence Awards

EthosEnergy Union Field Services wins silver at Safety Excellence Awards

|

News

|

25 May 2022

|

|

EthosEnergy’s hydrogen technology can support in the global transition to sustainable energy

EthosEnergy’s hydrogen technology can support in the global transition to sustainable energy

|

News

|

19 May 2022

|

|

Hydrogen Europe appoint EthosEnergy’s VP Engineering as Skills working group Co-Chair

Hydrogen Europe appoint EthosEnergy’s VP Engineering as Skills working group Co-Chair

|

News

|

17 March 2022

|

|

Is Hydrogen the Silver Bullet Answer to Emissions Reduction?

Is Hydrogen the Silver Bullet Answer to Emissions Reduction?

|

Views

|

17 February 2022

|

|

Red Rock Biofuels selects EthosEnergy as Asset Management partner

Red Rock Biofuels selects EthosEnergy as Asset Management partner

|

Impact

|

15 February 2022

|

|

EthosEnergy wins EIC's Culture Award

EthosEnergy wins EIC's Culture Award

|

News

|

03 December 2021

|

|

Top Executive Award 2021

Top Executive Award 2021

|

News

|

19 October 2021

|

|

EthosEnergy reveals refreshed brand and new digital experience

EthosEnergy reveals refreshed brand and new digital experience

|

Views

|

18 October 2021

|

|

EthosEnergy features in Turbomachinery International Magazine’s issue on Cybercrime and Control Systems

EthosEnergy features in Turbomachinery International Magazine’s issue on Cybercrime and Control Systems

|

Impact

|

12 August 2021

|

|

EthosEnergy awarded multi-million dollar operations and maintenance contract extension by TexGen Power

EthosEnergy awarded multi-million dollar operations and maintenance contract extension by TexGen Power

|

News

|

22 June 2021

|

|

EthosEnergy hosts “Our Hydrogen Future Roundtable” on EU emissions

EthosEnergy hosts “Our Hydrogen Future Roundtable” on EU emissions

|

News

|

08 June 2021

|

|

EthosEnergy and Politecnico di Torino partner to develop hydrogen technology for next generation turbine conversion

EthosEnergy and Politecnico di Torino partner to develop hydrogen technology for next generation turbine conversion

|

News

|

19 May 2021

|

|

Co-hosting North Sea Decarbonisation Conference

Co-hosting North Sea Decarbonisation Conference

|

News

|

14 May 2021

|

|

How is EthosEnergy building corporate values and culture during a global pandemic?

How is EthosEnergy building corporate values and culture during a global pandemic?

|

Social

|

03 May 2021

|

|

Turbomachinery International features EthosEnergy in this month’s cover story

Turbomachinery International features EthosEnergy in this month’s cover story

|

Impact

|

15 April 2021

|

|

Ana’s first year

Ana’s first year

|

Views

|

06 January 2021

|

|

Shanahan Engineering awarded a multi-million dollar construction management contract by Energy Services LLC

Shanahan Engineering awarded a multi-million dollar construction management contract by Energy Services LLC

|

News

|

22 October 2020

|

|

Adapting to the environment

Adapting to the environment

|

Impact

|

14 July 2020

|

|

Keeping key workers safe

Keeping key workers safe

|

Social

|

03 June 2020

|

|

EthosEnergy awarded five year multi-million pound turbine maintenance contract by a major North Sea operator

EthosEnergy awarded five year multi-million pound turbine maintenance contract by a major North Sea operator

|

News

|

20 May 2020

|

|

EthosEnergy improves accessories and components operations in Aberdeen with new sustainable facility

EthosEnergy improves accessories and components operations in Aberdeen with new sustainable facility

|

News

|

21 April 2020

|

|

EthosEnergy awarded operations and maintenance contract in Panama by SINOLAM SMARTER ENERGY worth over $36M

EthosEnergy awarded operations and maintenance contract in Panama by SINOLAM SMARTER ENERGY worth over $36M

|

News

|

05 March 2020

|

|

EthosEnergy CEO named on WomenInc.’s most influential corporate board directors

EthosEnergy CEO named on WomenInc.’s most influential corporate board directors

|

News

|

18 February 2020

|

|

Apprenticeship success

Apprenticeship success

|

Social

|

06 February 2020

|

|

EthosEnergy takes over operations and maintenance of Louisiana cogeneration facility for ExxonMobil

EthosEnergy takes over operations and maintenance of Louisiana cogeneration facility for ExxonMobil

|

News

|

31 July 2019

|

|

3,000 days in Rusail

3,000 days in Rusail

|

News

|

19 September 2017

|

|